From Afterthought to Advantage

Mark Krajewski and Justin Rispoli, Aspen Aerogels Inc., showcase the critical role of aerogel insulation in optimizing LNG asset design, and how its superior thermal performance, durability, and space- saving properties contribute to enhanced efficiency, optimized design, and long-term value.

As the world’s need for energy ever increases, the engineers and owners that build and commission the next generation of energy supply facilities are compelled to build them faster, more efficiently, and with a lower total carbon impact.

These macro pressures are driving stakeholders in the plant development process to seek out every possible advantage, no matter how subtle, to meet these objectives.

Regardless of the construction mode utilized, whether completely stick built or state-of-the-art modular construction, doing more with less and doing it faster is the goal. However, as the mode of construction switches from stick built to 100% modular, the importance of design and build efficiency is amplified.

In the world of modular construction, space and weight are the two most precious commodities for design engineers. Although possible, it is incredibly difficult to quantify what each additional pound of weight or inch of space means in the design of a module. What is certain, though, is that removing weight and saving space is the desire of everyone involved in a modular project.

When asked to share his thoughts on the importance of space and weight in the design, construction, and transport of modules, Program Director and modular construction specialist Kacey Sutton of KBR offered the following insights:

“In modularization the reduction of weight and space required for items is almost an unmeasurable value. Weight and space reduction plays a major factor in almost every aspect of the engineering and construction of modules: the space for access and maintenance around piping and equipment; the equipment—such as cranes and SPMTs—required for the construction, transport, and installation of modules is based on the overall size and weight; the sizing of structural steel is based on the weight and loads of piping, equipment, and other items; and many other factors are related to these two metrics. And for modules, the single largest cost constraint is the shipping and transport, which is almost completely driven by the weight, size, and space of the modules. So, every square inch and pound are of the utmost importance in the overall picture.”

It is incumbent on the designer to pursue every opportunity for potential weight and space savings. There is one that can provide a significant impact, but it’s often overlooked: the insulation system.

Traditional insulation systems are big, bulky, and add unavoidable weight. Now consider that most FLNGs, FPSOs, and FSRUs have many dual service applications like cold and acoustic protection or cold and passive fire protection, and those already big, bulky, and heavy insulation systems can balloon up in size and weight even further. This article aims to show a simple and effective way to save both space and weight by utilizing a solution proven to be superior in thermal resistance, passive fire protection, and sound attenuation (decibel insertion loss): an aerogel insulation blanket.

Design Efficiency

The designers of offshore facilities are always looking for opportunities to improve the efficiency of a facility, while also meeting the mandated design goals. Those goals typically include name plate capacity, worker safety, compliance with emissions regulations, and resistance to catastrophic events such as hurricanes and fires. The designer is somewhat constrained as the number of pipes and their diameter, metallurgy, and wall thickness are all fixed by the process design, which in turn is dictated by the size and number of process units in the facility. Traditional thought would box that design into standard rules of thumb about pipe spacing and rack structures based not on the size of the pipes themselves, but on the outside diameter of the insulated pipe. That metric, which was traditionally viewed as fixed, is now a meaningful lever the designer can use to reduce the footprint of the facility.

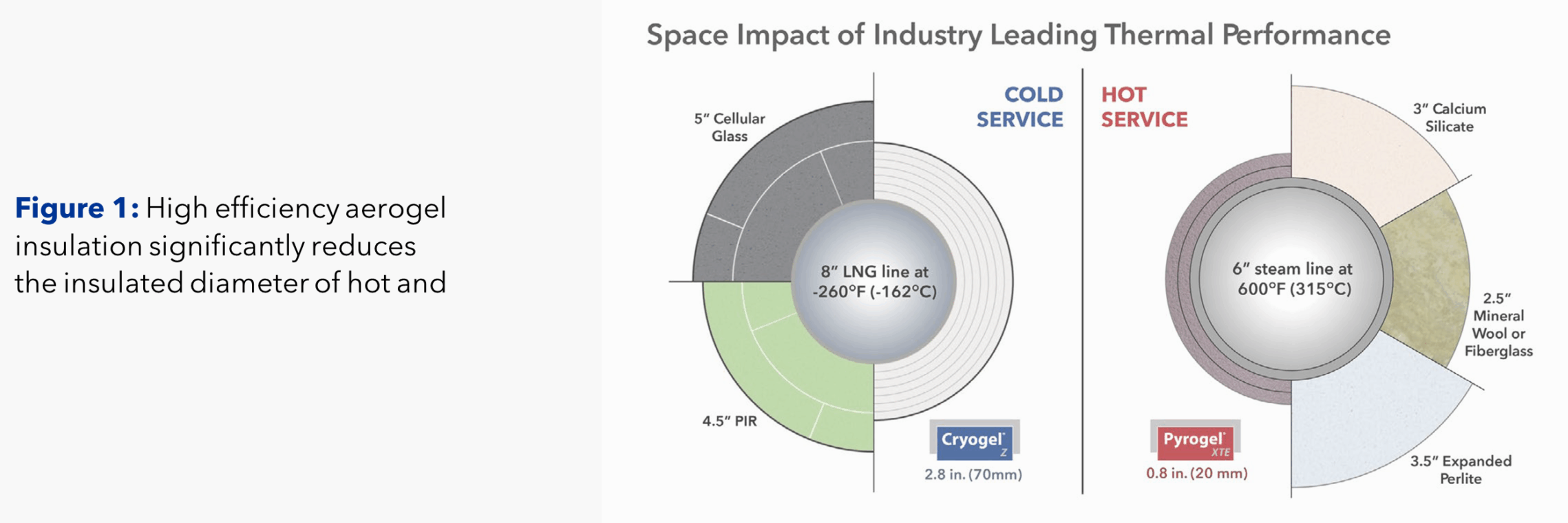

Figure 1 depicts a cross section of hot service and cold service piping with comparable insulation thickness to meet standard thermal design goals. On the cold side, the design goal is a condensation control criterion. In this example, all three insulations would have roughly the same surface temperature and propensity to condense ambient moisture on the insulation jacket during high humidity weather patterns.

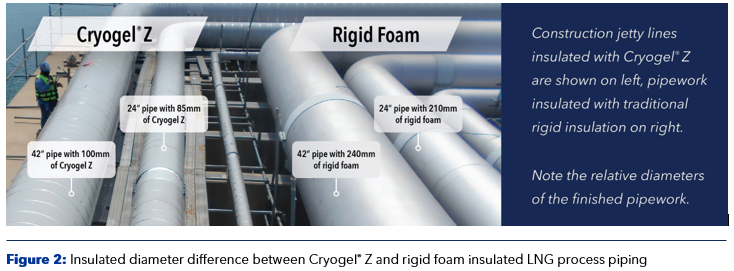

By using Cryogel® Z high efficiency aerogel based thermal insulation, the insulated diameter of the pipe decreases from 18.625” to 14.225” a reduction of about 24%. Just by using more efficient insulation, the designer could place five lines in the same space that four lines occupied before. The same holds true for hot work where we see a reduction from a maximum insulated diameter of 13.5” to 8.1”; a reduction of 40%. A real-world manifestation of this effect can be seen in Figure 2 where two LNG jetty lines are running side by side, one insulated with traditional rigid insulation materials, and one insulated with Cryogel® Z.

According to Ryan Whitley, Vice President at State Service, a popular modular yard in Ingleside, TX:

“Overall size and weight are two critical components of the design and execution of modular construction projects. The ability to reduce weight and/or save space, without sacrificing safety or performance, is advantageous.”

Layer in the incredibly complex and stringent design conditions for offshore facilities like FLNGs, FPSOs, and FSRUs and you have an even bigger challenge to make things smaller and lighter.

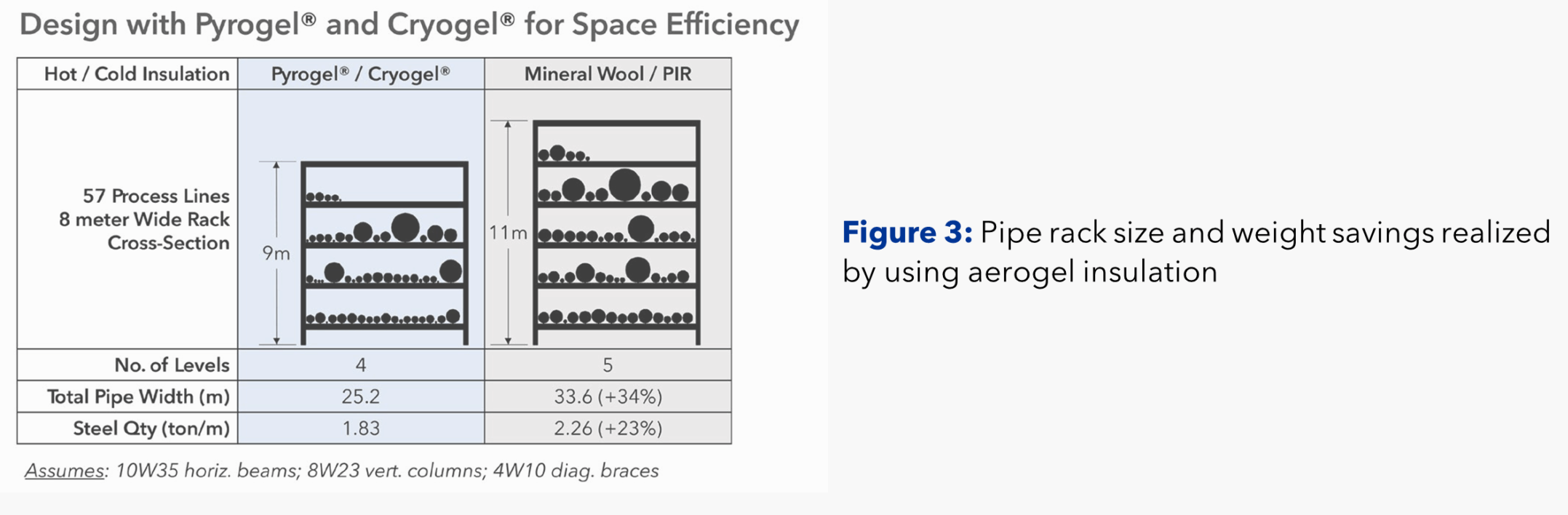

What if we take this diameter reduction and look at the impact across a variety of different process temperatures and diameters? In Figure 3, that difference is detailed for a pipe rack that has 57 different process lines. With the example piping and process temperature, the insulation thickness differential allows for the removal of an entire level of the rack, saving 1.83 tons of structural steel per meter of rack. In FLNG assets where every pound of topside mass is critical, the value is clear.

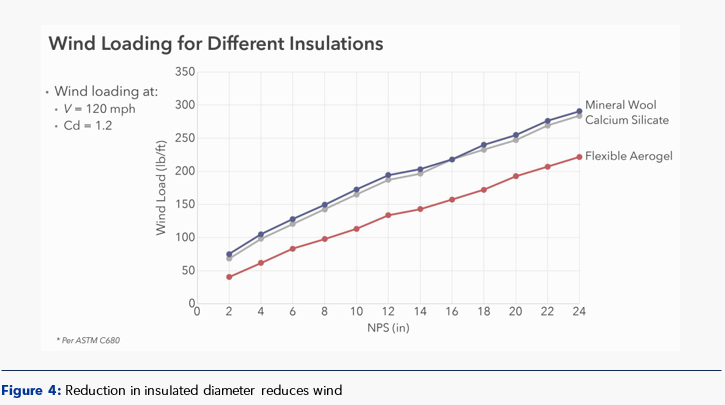

The reduction in the insulation outer diameter not only has a positive impact on rack design but it can also have a proportional effect on the wind loading the pipe rack will experience. Figure 4 details the wind loading a linear foot of insulated pipe will experience when subjected to a 120- mph wind event. Wind load is one of the driving factors in the rack strength requirements on both terrestrial and floating assets. For a terrestrial asset, the effects of loading end at the bottom of the rack and foundation requirements. For a floating asset, there are stability considerations to design for as well. In the floating case, the effective length the wind load is acting on is the center of rotation of the structure, which can be multiples of moment arm longer than where the rack meets the hull supporting structure. This magnifies the benefit that any reduction in wind loading can have, by reducing the insulated pipe diameter. Not only can you reduce the weight of the supporting structures, but your buoyancy and stability calculations receive a benefit as well.

FLNG requires multifaceted protection for piping and equipment

Amongst the different design requirements mandated for FLNG facilities, many are related to safety for the operators and others that work on and around the facility. These multi-faceted design requirements are becoming more common as the next generations of facilities are being proposed and designed. A recent example of this is the advent of the protection requirements against cold spillage, which are now quantified in the ISO- 20088 series of standards.

There have always been passive fire protection requirements on offshore facilities, but those, too, are becoming more prevalent and sophisticated in their use and specification. These protection regimes are now often sequential where a system is first subject to impingement by a cryogenic liquid then exposed to a jet fire.

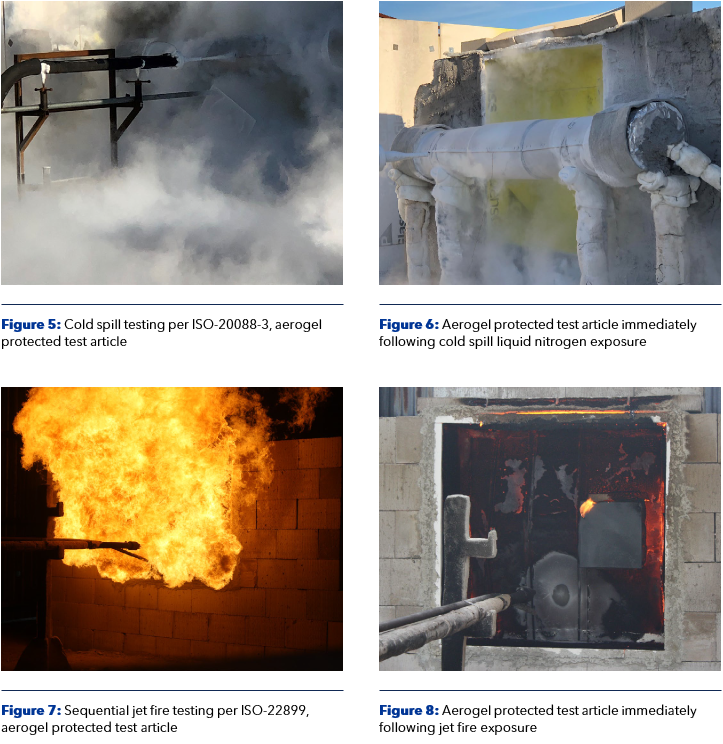

The thermal shock of going from liquid nitrogen temperatures (-196C) to jet fire temperatures 1250C is extreme to say the least. Notably, both Pyrogel® and Cryogel® Z aerogel insulations have been tested against these dual protection regimes using the ISO-20088-3 and ISO-22899 standards and have achieved type approvals for a variety of configurations, durations, and Hp/A ratios (Figures 5-8) in a single solution. Traditional thermal insulation systems require separate systems for thermal design and passive fire protection, adding additional weight and complexity.

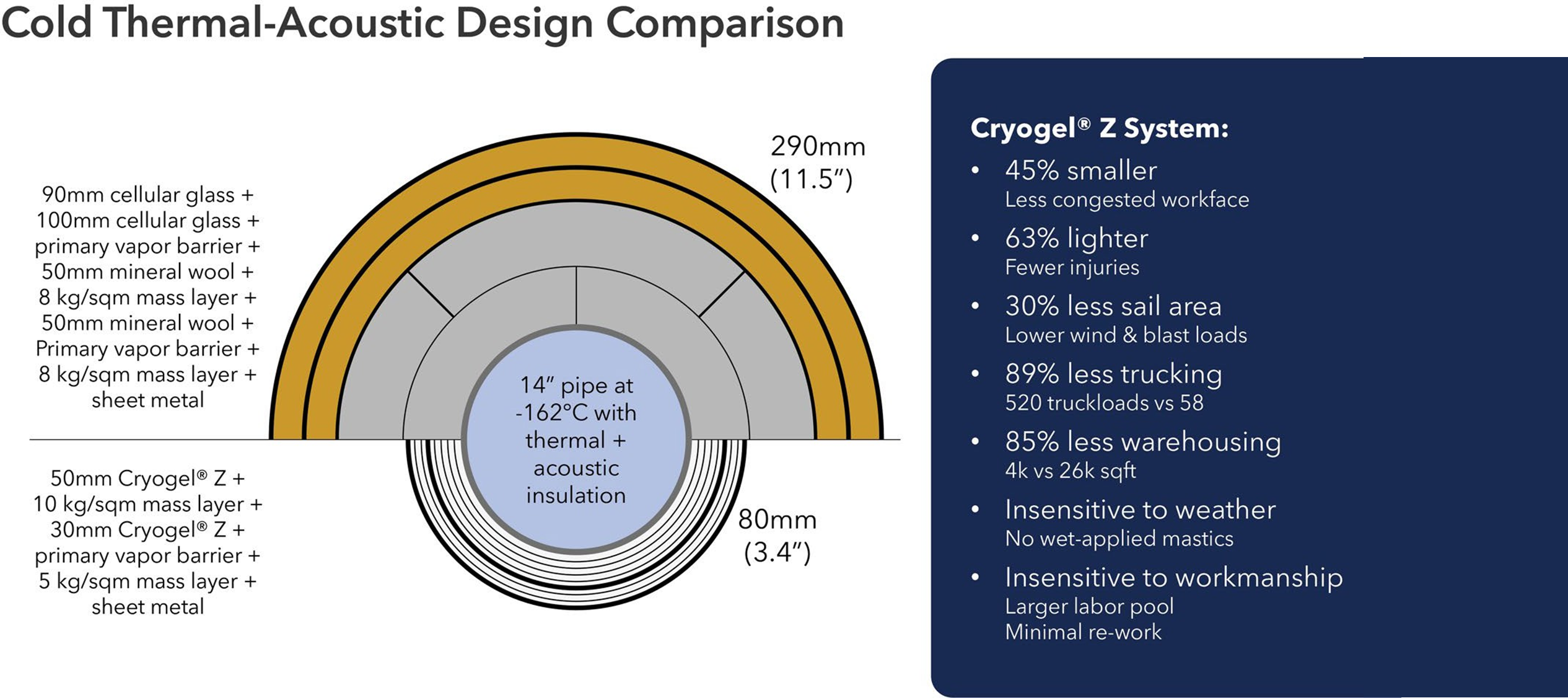

LNG and FLNG facilities often require insulation systems that will meet a thermal design requirement and provide sound power reduction per ISO-15665. The high velocity gas movements in LNG facilities are a major source of noise. Much like passive fire and cold spillage applications, traditional rigid cryogenic insulation systems cannot provide the dual thermal and acoustical benefit on their own, necessitating two separate insulation systems to be applied to the same pipe (Figure 9); one thermal and one purely acoustical, where the thermal system provides no acoustical benefit, and the acoustical system cannot be counted as providing thermal benefit.

Additionally, since this is cold work, both systems must be carefully vapor sealed. Cryogel® Z aerogel insulation, on the other hand, can provide both thermal and acoustical benefit from the same material. In the example in Figure 9, Cryogel® Z insulation can achieve the desired thermal design and a Shell Class D acoustical rating with only 3.2” of thickness. The efficiency benefit to the designer is profound as the Cryogel® Z aerogel insulation system is less than one third as thick as the traditional system, all while being far easier to install and with a lower total installed cost.

Ease of installation and operational benefits

Clearly the focus of this article is to present data on the potential value these materials can provide when they are used to enhance plant design. It would be remiss if some of the operational and installation benefits of the materials weren’t also discussed. Insulation contractors who have worked on a past major FLNG project, stated their productivity offshore amounted to approximately 90 minutes of actual time on the tools, for every 10-hour shift an insulator participated in, a 15% tool time metric. In a well-designed and controlled study, Cryogel® Z insulation installed approximately 30% faster than a traditional rigid insulation. This is a benefit for any cryogenic installation, but when the effective time installing materials hovers in the 15% range, it is a game changer.

Cryogel® Z insulation does not require contraction joints, which are necessary in rigid insulation system, are difficult to install, and prone to failure. From an operational standpoint, if you are designing to condensation control criteria, you will have less boil off gas just by specifying Cryogel® Z insulation; in some cases, up to 50% less depending on pipe size and thermal requirements. Cryogel® Z aerogel insulation is easy to inspect, is reusable, and will not crack or embrittle at cryogenic temperatures. Simply put, it is just a better form factor for cryogenic insulation.

Conclusion

A recent conversation with Tom Lyons, team leader for Integrity, Corrosion & Materials group with Wood PLC, nicely summarizes the value flexible aerogel insulation can bring to the designer of FLNG assets:

“Weight and space are serious concerns offshore and nowhere is this more important than in the FLNG business. LNG liquefaction units require a lot of insulation, which is traditionally bulky and has a surprisingly high contribution to the overall weight on topsides FLNG. After multiple layers of thick insulation is applied even to small pipe, valuable deck and pipe rack space can be taken up quickly. Aerogels such as Cryogel® insulation are lightweight and generally more compact, making them ideally suited for FLNG.”

In the ever-increasing quest to make the next generation of onshore and offshore LNG facilities more efficient, lower cost, and reduce the total carbon footprint, a powerful new tool has emerged from a most unlikely source: thermal insulation. Insulation using aerogel technology can be a major facilitator towards those goals, but only if you design for it.

Get in touch with our talented engineers for help with your next project.