Thermal Runaway Barriers

Mechanical & Thermal Performance You Can Trust Through EOL

Developed for pouch and prismatic applications, PyroThin cell-to-cell barriers help battery engineers achieve safety and performance goals for modules and packs with LFP, NMC, and solid-state chemistries.

Each PyroThin part combines Aspen’s patent-protected Aerogel Technology Platform® with our team’s comprehensive understanding of complex thermal runaway events in electric vehicles (EV) and energy storage systems (ESS).

What is Critical for a Thermal Barrier/Compression Pad?

PyroThin’s Proven Performance

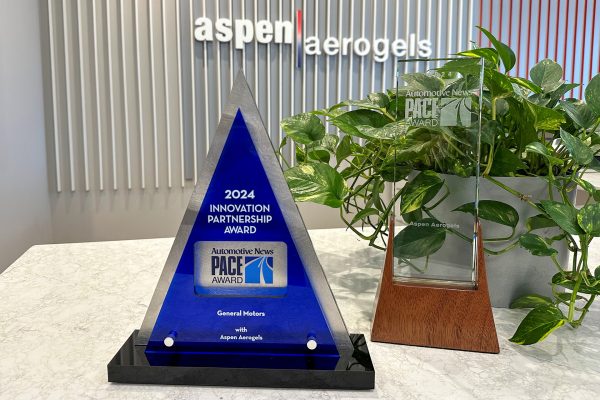

In 2024, PyroThin won Automotive News PACE and Innovation Partnership Awards. The Innovation Partnership Award recognizes our extensive collaboration with General Motors as the thermal runaway solution for its Ultium battery platform.

Aspen Aerogels was also named 2022’s Overdrive Award Winner for Launch Excellence, as part of General Motors’ 30th Supplier of the Year Award. PyroThin’s proprietary technology and Aspen’s agile engineering support played a crucial role in GM’s thermal propagation strategy for their Ultium battery platform.

PyroThin C2C barriers are in volume production for major automotive OEMs in North America, Europe, and Asia.

Request More Information

PyroThin thermal barriers are an engineered part and not an off-the-shelf material, so specifications will vary depending on an application’s requirements. Please fill out the form to discuss your project with our technical team.

Why Partner with Aspen?

Trusted, Scalable Solutions

We are a Tier 1 supplier in volume production with global automotive OEMs

Aerogel Technology Experts

From formulating the aerogel’s chemistry to part manufacturing, PyroThin cell-to-cell (C2C) barriers are designed, engineered, and produced by Aspen

Extension of Your Team

Global engineering and customer service ready to support in your local language and time zone

Aerogel C2C Barriers ≠ PyroThin

All aerogel is not created equal. PyroThin’s aerogel technology delivers performance you cannot get anywhere else