A Case of Remedy: Overcoming Yield Loss Through Aerogel Treatment

Insulation has historically been considered less critical compared to other equipment in an oil and gas plant. However, that traditional mindset is fast-changing, as oil majors who invested in superior aerogel insulation have witnessed vast benefits in improved production yield, turnaround time, and asset reliability.

One such case happened on a tropical coast of Southeast Asia, where a major petrochemical complex met persisting issues in achieving the temperature level that is critical for their production efficiency. Left unattended, the below optimal temperature of gas streams flowing to the Continuous Catalytic Regenerator (CCR) can negatively impact production yield.

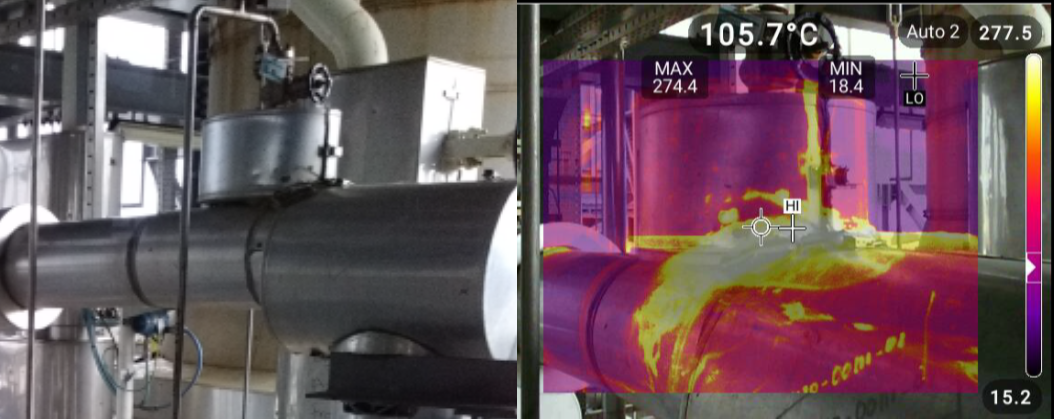

To remedy the situation, they reached out to Aspen Aerogels, and we deployed a team of Technical Services engineers to help investigate the root cause. Insights from data, discussions, and a simulation were not conclusive, but were indicative of a few weak spots in their CCR insulation. Thermal imaging scans confirmed that the issue was insufficient insulation and poor installation at certain areas between the CCR unit and its adjacent Catalytic Reformer Reactors (CRR), where the core catalytic reforming reaction occurs.

Before

“From design to construction, and from operation to maintenance, leading insulation specialist Aspen Aerogels is fielding its Technical Services engineers to help customers bring new and existing energy infrastructures back to health.”

After

“As one of the lowest thermal conductivity materials in the world, Pyrogel® insulation was specified and installed to help achieve the desired outlet temperature and to improve production yield.”

Catalytic reforming converts naphtha into premium high-octane feedstock for gasoline blending, using expensive platinum catalyst to improve yield of reforming reaction. The platinum catalyst is reactivated in the CCR where temperature is a key parameter that determines the extent of the restoration back to the initial catalyst activity, defining the lifespan of this expensive catalyst. Due to the critical nature of this unit, the customer only agreed to 6 days shutdown for rectification work. Adding to the challenge, the identified piping route to the CCR is located 20 meters above ground, with limited space to maneuver.

To perform the re-insulation work, two teams of contractors were deployed, including some contractors with little or no experience with the installation of Pyrogel® insulation. The simplicity of Pyrogel insulation made for easy and fast work, even with the inexperienced contractors and minimal supervision. The versatility and lightweight properties of Pyrogel insulation also enabled contractors to pre-cut the materials and carry them up to the work location faster and safer.

Re-insulation work was completed on day 5. The unique characteristics of Pyrogel aerogel insulation allowed the customer to proceed with startup while jacketing was being completed, providing a return to service 24-hours ahead of schedule.

After startup, the CCR unit achieved its required temperatures, and the electrical heater ran at lower load with substantial power savings. Subsequent inspection with thermal imaging scans found that the heat loss areas were now meeting the expected standard and the issue had been remedied.

During project close-out, the customer expressed their gratitude to the Aspen Aerogels Technical Services team for its commitment and effort to resolve the issue. The customer’s satisfaction with the newly achieved thermal performance resulted in this form of insulation being established as a best practice guideline.

Guess who’s invited back to health-check their next major turnaround?

References

Argyle, Morris & Bartholomew, Calvin. (2015). Heterogeneous Catalyst Deactivation and Regeneration: A Review. Catalysts. 5. 145-269. 10.3390/catal5010145.

Continuous Catalytic Reforming. (n.d.-c). Chromalox| Process Heating Solution| Application. https://www.chromalox.com/en/solutions/process-heating-solutions/applications/continuous-catalytic-reforming

Continuous Catalyst Regeneration | FSC 432: Petroleum Refining. (n.d.). https://www.e-education.psu.edu/fsc432/content/continuous-catalyst-regeneration

Gupta, A., & Gupta, S. K. (2022). Catalyst Regeneration Techniques in Naphtha Reforming: Short Review. Chemical and Process Engineering, 43(2). https://doi.org/10.24425/cpe.2022.140813

Hawkins, G. B. (n.d.). Catalytic Reforming: Catalyst, Process Technology and Operations Overview. https://www.slideshare.net/GerardBHawkins/catalytic-reforming-catalyst-process-technology-and-operations-overview

Laura Janette, B. (1988). Redispersion Reactions of Platinum/Alumina Reforming Catalysts [PhD thesis]. University of Glasgow.

Pujadó, P.R., Moser, M. (2008). Catalytic reforming. In: Jones, D.S.J.S., Pujadó, P.R. (eds) Handbook of Petroleum Processing. Springer, Dordrecht. https://doi.org/10.1007/1-4020-2820-2_5

Contact an Aspen Aerogels technical services engineer today